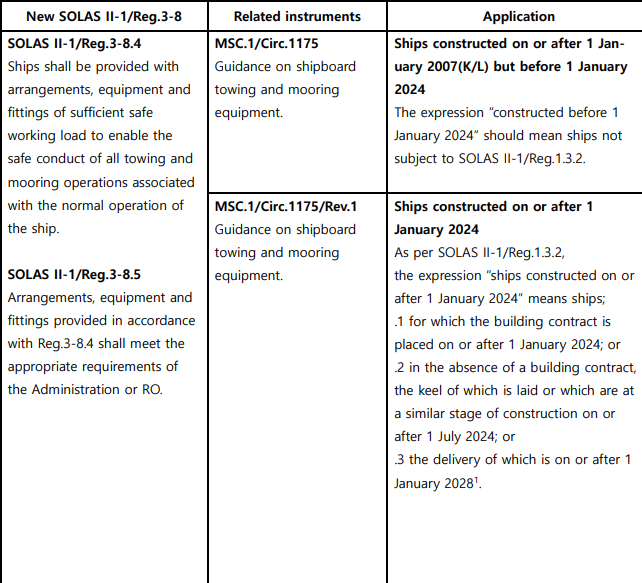

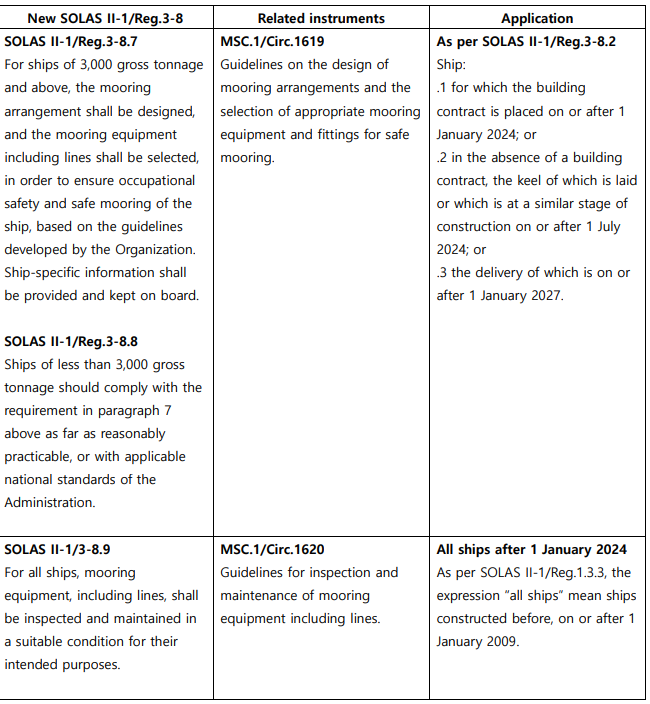

Amendments to SOLAS II-1/Reg.3-8 “Towing and mooring equipment” were adopted by the Maritime Safety Committee at MSC 102 and will enter into force on or after 1 January 2024.

In particular, these amendments introduce new safety requirements for design, selection, inspection, maintenances and replacement of mooring and towing arrangements in conjunction with MSC.1/Circ.1175/ Rev.1, MSC.1/Circ.1619 and MSC.1/Circ.1620.

Background

New ship designs, and especially the design of large ships, have resulted in optimized performance and a greater degree of complexity. It is, however, a widely recognized fact that the development and design of mooring systems has not adequately followed the development of ships. Despite efforts to improve how safe mooring operations, we still experience a high number of accidents during these operations.

Definition for towing and mooring equipment

- Safe Working Load (SWL) means the safe load limit of shipboard fittings used for mooring operations.

- Ship Design Minimum Breaking Load (MBLSD) means the minimum breaking load of new, dry mooring lines for which shipboard fittings and supporting hull structures are designed in order to meet mooring restraint requirements or the towing requirements of other towing service.

- Line Design Break Force (LDBF) means the minimum force at which a new, dry, spliced mooring line will break at. This is for all synthetic cordage material. This value is declared by the manufacturer on each line’s mooring line certificate and data sheet. LDBF of a line should be 100%-105% of the ship design minimum breaking load (MBLSD).

- Working Load Limit (WLL): the maximum load that a mooring line should be subjected to in operational service. The WLL is expressed as a percentage of MBLSD and should be used as a limiting value in operational mooring analyses. Steel wires have a WLL of 55% of MBLSD and all other cordage (synthetic) have a WLL of 50% of the MBLSD.

- Bend radius (D/d ratio) means the diameter (D) of a mooring fitting divided by the diameter (d) of a mooring line that is led around or through the fitting.

- Towing and mooring arrangements plan means the plan as described in section 5 of the annex to the revised guidance on shipboard towing and mooring equipment (MSC.1/Circ.1175/Rev.1). This plan presents specific information regarding the towing and mooring fittings aboard the vessel, the mooring lines, as well as the arrangement of mooring lines and the acceptable environmental conditions for mooring.

`

`

Credits: KR

New regulation and instruments for towing and mooring equipment (SOLAS II-1/Reg.3-8)

Actions to be taken

1.While applying the SOLAS II-1/Reg.3-8.4, 3-8.5 and 3-8.8, for new ships of less than 3,000 gross tonnage, the following is prepared on board:

- The “Towing and mooring arrangements plan” should provide the following;

- The maximum brake holding load of mooring winches

- Information according to the paragraph 5 of MSC.1/Circ.1175/Rev.1

- A mill sheet of the mooring lines;

- The properties of mooring lines related to LDBF and bend radius (D/d ratio).

- Including warning that the wear rate of lines may be higher for lower diameter. (paragraph 5.6 of MSC.1/Circ.1620)

- At initial survey of the ship, the surveyor should confirm that the plan and documents should be provided on board for the above information.

2. While applying the SOLAS II-1/Reg.3-8.4, 3-8.5 and 3-8.7, for new ships of 3,000 gross tonnage and above, the following should be prepared on board in addition to those specific above 1):

- A document should be provided for information and as a supplement to the towing and mooring arrangements plan, confirming that MSC.1/Circ.1619 has been considered;

- Justification and suitable safety measures related to the deviations from requirements in MSC.1/Circ.1620 should be provided included in the supplement to the towing and mooring arrangements plan if there are deviations (paragraph 6 of MSC.1/Circ.1619);

- If deviations are not found necessary, and the supplement is not needed, then this should be mentioned explicitly in the towing and mooring arrangements plan;

- The maximum brake holding load of mooring winches should be less than 100% of the Ship Design Minimum Breaking Load (MBLSD) (paragraphs 5.2.3.3 and 5.2.4 of MSC.1/Circ.1619); and

- The winches should be fitted with brakes that allow for the reliable setting of the brake rendering load.

- At initial survey of the ship, the surveyor should confirm that the towing and mooring arrangements plan and the supplement describing deviations and suitable safety measures are provided on board.